In the electronics manufacturing sector, precise packaging of DuPont wires is a critical factor in enhancing production efficiency and controlling costs. This guide provides professional insights into technical selection, application scenarios, and industry practices, combined with the innovative solutions from Guangdong Tianxuan Packaging Machinery Co., Ltd., to help optimize your packaging processes.

1. Key Technical Parameters Analysis

-

Cutting Precision & Packaging Speed

DuPont wire packaging requires a balance between ±0.5mm cutting precision and 20-40 wires/minute packaging speed. The Tianxuan TX-1121 DuPont wire packaging machine is equipped with a Japanese servo drive system and fiber optic positioning technology, achieving a length error of ≤0.3mm per wire with automatic calibration, significantly reducing manual adjustment costs. Its intelligent heat-sealing module adapts to PE, PVC, and other packaging materials, with a 99.8% heat-sealing pass rate and CE/ISO9001 certifications. -

Wire Management Compatibility

To address the tangling issue of DuPont wires, the machine uses a customized vibrating plate feeding system with tension sensors and flexible grippers, automatically sorting wires with diameters of 0.1-1.0mm and reducing 85% of manual sorting time. Mold adjustment takes only 15 minutes for different wire specifications, suitable for multi-variety, small-batch production. -

Energy Consumption & Maintenance Cost

Opt for low-power models (e.g., TX-1121 with 1.5kW rated power) and prioritize ease of maintenance. Tianxuan promises 48-hour global after-sales response, using imported components (Omron sensors, Delta servo motors) to ensure an MTBF of over 8,000 hours, reducing maintenance costs by 30% compared to similar devices.

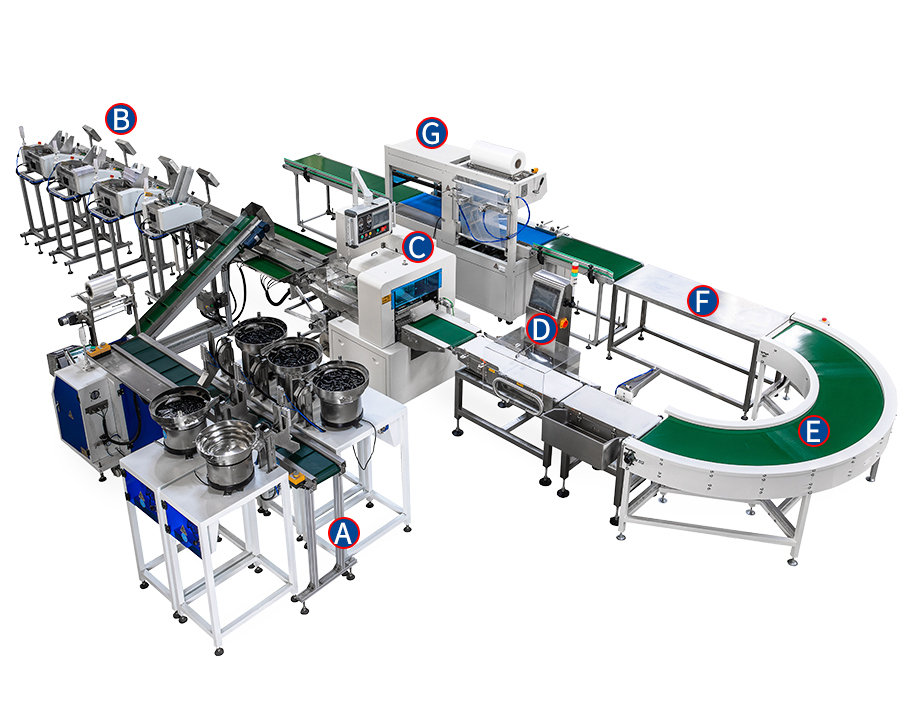

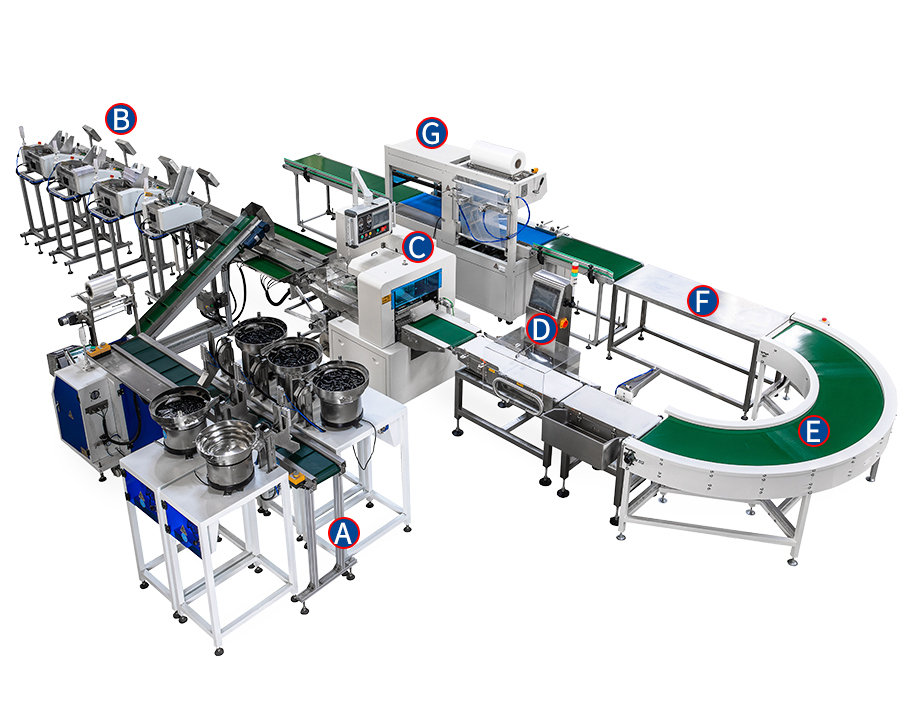

2. Typical Application Scenarios

- Standard Batch Packaging: Tianxuan’s vertical DuPont wire packaging machine integrates a Mitsubishi PLC control system, supporting fully automated counting, heat-sealing, and batch printing for large-scale production of electronic harnesses and test cables.

- Multi-Specification Mixed Packaging: The four-channel combined model handles 2-4 wire lengths simultaneously, enabling precise sorting for smart device kits and laboratory equipment sets.

- Non-Standard Customization: For terminal-connected or special-shaped wires, Tianxuan provides customized magnetic sorting fixtures, solving orientation challenges for L-type terminal wires in automotive electronics and accommodating complex structures.

3. Advantages of Professional Packaging Machine Manufacturer

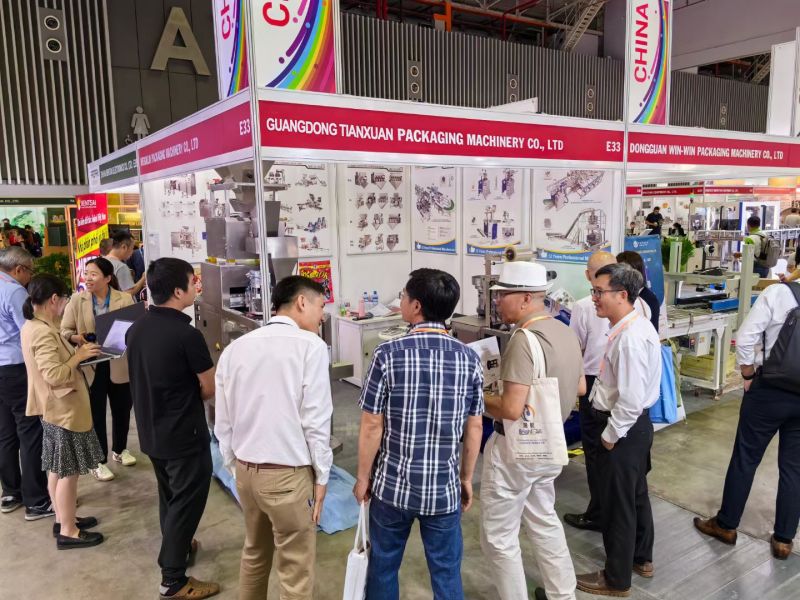

As a leading accessory packaging machine manufacturer in the electronics packaging field, Guangdong Tianxuan Packaging Machinery offers three core strengths:

- R&D Innovation: With 23 patents, including a dual-station switching system (Patent No.: CN2023XXXXXX) that increases 产能 by 50% and supports film replacement without shutdown.

- Precision Manufacturing: Key components (cutting blades, wire guides) are made from German imported steel, processed with high-precision equipment to ensure ±0.01mm accuracy, extending equipment life by 25% above industry average.

- Global Service Network: Providing one-stop services from design to training, having optimized packaging lines for 300+ electronics enterprises worldwide, with typical cases showing a 40% efficiency increase and 60% labor cost reduction.

4. Selection & Cost-Saving Tips

- Small-Medium Enterprises: Choose Tianxuan’s 200-series single-channel model, replacing 4-6 workers with a 12-18 month payback period, ideal for sample production and medium batches.

- Large-Scale Production Lines: Deploy multi-machine 联动 systems integrated with robotic sorting and smart warehousing for unmanned operations, reducing overall energy consumption by over 20%.

When selecting a DuPont wire packaging machine, test its compatibility with wires, long-term stability, and after-sales response. As a professional packaging machine manufacturer, Tianxuan’s solutions are widely used in consumer electronics and industrial control, helping enterprises upgrade packaging efficiency and optimize costs.

Post time: Apr-24-2025