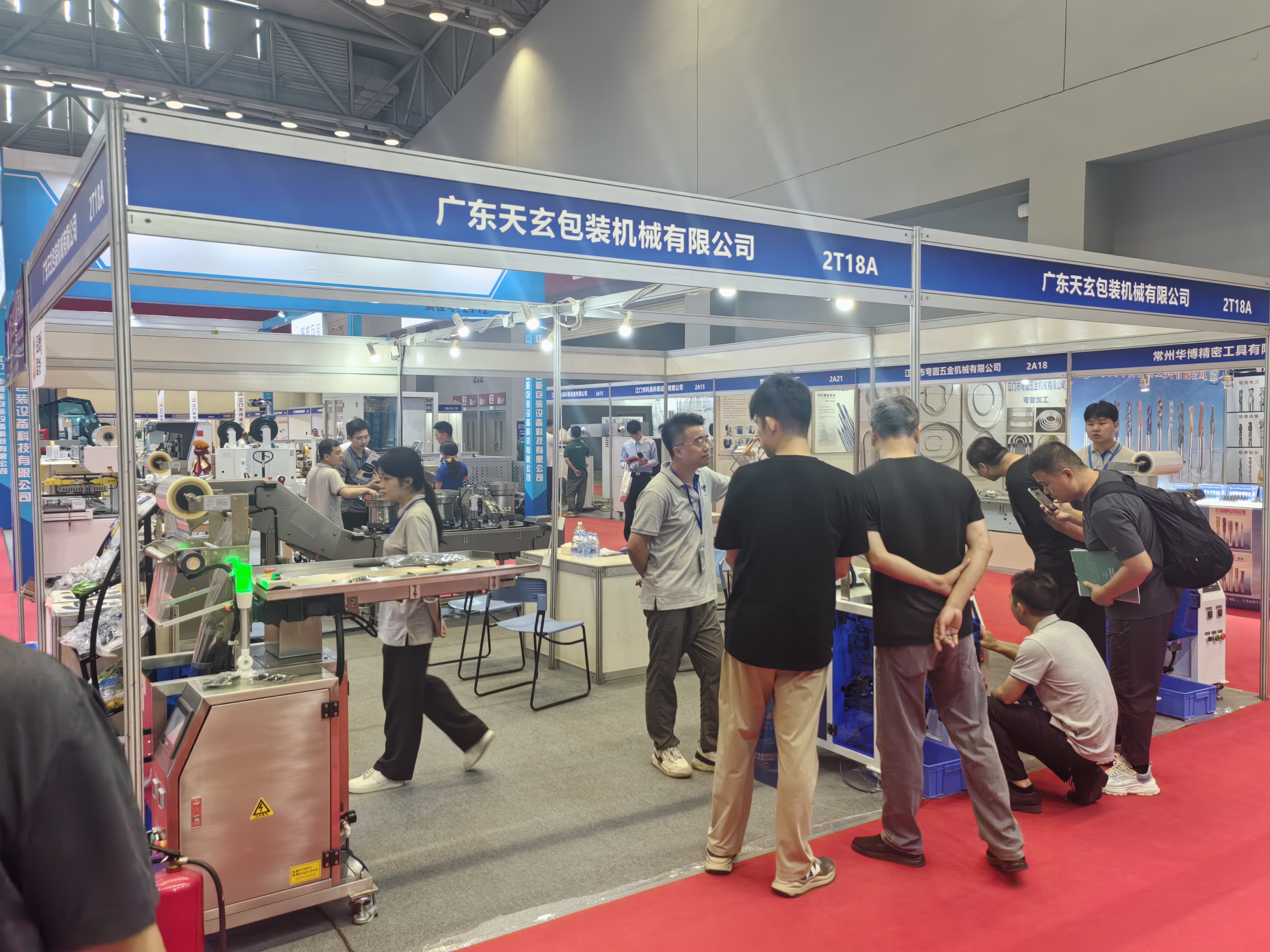

April 24, 2025, Jiangmen Pearl River West International Convention and Exhibition Center – At the 13th Jiangmen Advanced Manufacturing Expo (April 24–26), Guangdong Tianxuan Packaging Machinery Co., Ltd. showcased its “Intelligent Packaging · Empowering Manufacturing” vision with a comprehensive smart packaging ecosystem at Booth B23-26. As a national high-tech enterprise, Tianxuan Machinery highlighted its intelligent DuPont wire packaging production line, multi-station accessory packaging system, and the industry’s first low-carbon hardware packaging machine, aiming to drive upgrades for the Greater Bay Area’s manufacturing sector.

1. Three Exhibition Zones Address Industry Pain Points with Technological Innovations

-

Intelligent Electronics Packaging Production Line Zone

Targeting the “multi-specification, small-batch” packaging needs of consumer electronics, Tianxuan demonstrated its Intelligent DuPont Wire Packaging Production Line, integrating automatic wire sorting, precision cutting (±0.5mm error), visual inspection, and robotic palletizing. This fully automated system, already adopted by a Shenzhen new energy vehicle wiring harness enterprise, has improved packaging efficiency by 60% and reduced error rates to below 0.1%. -

Flexible Accessory Packaging Solutions Zone

The newly launched four-axis 联动 accessory packaging machine drew significant attention, featuring proprietary magnetic quick-change mold technology (Patent No.: CN2025081234) that switches between screws, gaskets, terminals, and other components in just 10 minutes. Supporting 1–6 material mixing, it caters to customized packaging for smart home components and automotive precision parts. Live demos showed 99.7% accuracy in identifying irregular clips, attracting procurement representatives from Midea, Galanz, and other enterprises. -

Green Manufacturing Technology Showcase Zone

Aligning with “double carbon” goals, Tianxuan unveiled the industry’s first low-carbon hardware packaging machine, equipped with energy-saving servo motors (40% lower energy consumption than traditional models) and an intelligent temperature-controlled heat-sealing system (reducing film waste by 30%). With a built-in waste recycling device, it achieves low-carbon transformation in packaging for sanitary hardware and construction profiles, certified by SGS for carbon neutrality compliance.

2. Multi-Dimensional Interactions Foster Industrial Collaboration, Strategic Partnerships Deepen Regional Layout

On the expo’s first day, Tianxuan held a “Smart Packaging Technology Seminar,” where Deputy General Manager Li Hongtao delivered a speech on “Flexible Packaging Upgrades in the Industry 4.0 Era,” sharing their AI-driven multi-material mixing solution for BYD New Energy Vehicles—shortening order delivery cycles by 30%. The company signed a strategic agreement with the Jiangmen High-Tech Zone Administration, planning a 50 million RMB investment in a “Greater Bay Area Smart Packaging R&D Center” to focus on unmanned packaging systems and IoT remote maintenance technologies.

In the customer experience zone, Tianxuan set up an interactive “Equipment Fault Simulation & Repair” session, demonstrating its 48-hour rapid response mechanism: 12 parameters, including servo motor temperature and heat-seal blade life, are monitored in real time via built-in IoT modules, with a 98% early warning accuracy. This digital service capability secured cooperation intentions from over 20 local manufacturers.

3. Rooted in the Greater Bay Area, Redefining Industry Standards Through Innovation

As a packaging machine manufacturer with 12 years of expertise, 70% of Tianxuan’s 20+ exhibited devices are proprietary patent products (29 intellectual property rights accumulated). Core technologies—such as the visual recognition system for accessory packaging machines and anti-tangle wire management for DuPont wire packaging—have become industry benchmarks. Data shows the company has saved over 200 million RMB in labor costs for South China enterprises in the past three years, upgrading more than 300 traditional production lines.

“We don’t just provide equipment; we build an ‘hardware+software+service’ smart packaging ecosystem,” said General Manager Mou Xinyu in a media interview. Leveraging the Greater Bay Area’s manufacturing cluster, Tianxuan will accelerate R&D of AI-driven packaging solutions to help more SMEs achieve “machine substitution” and cost efficiency.

The expo runs through April 26, with Tianxuan’s booth offering equipment customization consultations and production line planning simulations. Welcome to Booth B23-26 to explore the future of smart packaging.

About Tianxuan Machinery

Founded in 2013, Guangdong Tianxuan Packaging Machinery Co., Ltd. specializes in R&D, manufacturing, and servicing smart packaging equipment, providing solutions for electronics, hardware, food, and other industries. Serving Fortune 500 companies like Hisense, BYD, and Haier, it has been named a “Top 10 Brand in China’s Packaging Machinery Industry” for three consecutive years.

Founded in 2013, Guangdong Tianxuan Packaging Machinery Co., Ltd. specializes in R&D, manufacturing, and servicing smart packaging equipment, providing solutions for electronics, hardware, food, and other industries. Serving Fortune 500 companies like Hisense, BYD, and Haier, it has been named a “Top 10 Brand in China’s Packaging Machinery Industry” for three consecutive years.

Post time: Apr-24-2025